Fagor Industrial

Washing away the competition by cutting time-to-market by up to 30 percent

Inspired by the evolution of smartphones, Fagor Industrial decided to launch a first-of-its-kind touchscreen washer extractor. With a short window of opportunity before competitors introduced similar products, the company achieved a rapid time-to-market by working with ULMA Embedded to develop the embedded systems using IBM® Rational® solutions.

Business challenge

Fagor Industrial spotted a chance to excite customers with a never-before-seen touchscreen washer extractor. To gain first-mover advantage, it needed to Design and launch this innovative product fast.

Transformation

To achieve a swift time-to-market, Fagor Industrial engaged IBM Business Partner® ULMA Embedded to develop its cutting-edge product using sophisticated IBM Rational development platforms.

Results

Up to 30%

reduction in time-to-market, enabling Fagor to gain first-mover advantage

25%

faster development of new embedded systems for a state-of-the-art product

Unlocks

huge time and cost savings by reducing the need to build physical prototypes

Business challenge story

Seizing a commercial opportunity

The success of touchscreen interfaces on smartphones has led to increasing numbers of other devices adopting touchscreen technology—including laptops, cash registers, ATMs and even cars. Observing consumers' keen appetite for touchscreens, and the greater usability they afford, Fagor Industrial set out to capitalize on this trend by launching an industrial washer extractor that can be controlled via a touchscreen interface.

At the time, no similar offerings were available on the market, but the clock was ticking. Fagor Industrial knew that first-mover advantage would be critical in this new product segment. To seize the narrow window of opportunity, the company needed to design, test and launch its new touchscreen offering as quickly as possible.

“With Rational, we can design and launch new products faster than ever, sharpening our competitive edge.”

— Imanol Lukas Etxarri, Electronic Engineer, Research and Development, Fagor Industrial

Transformation story

Calling in the experts

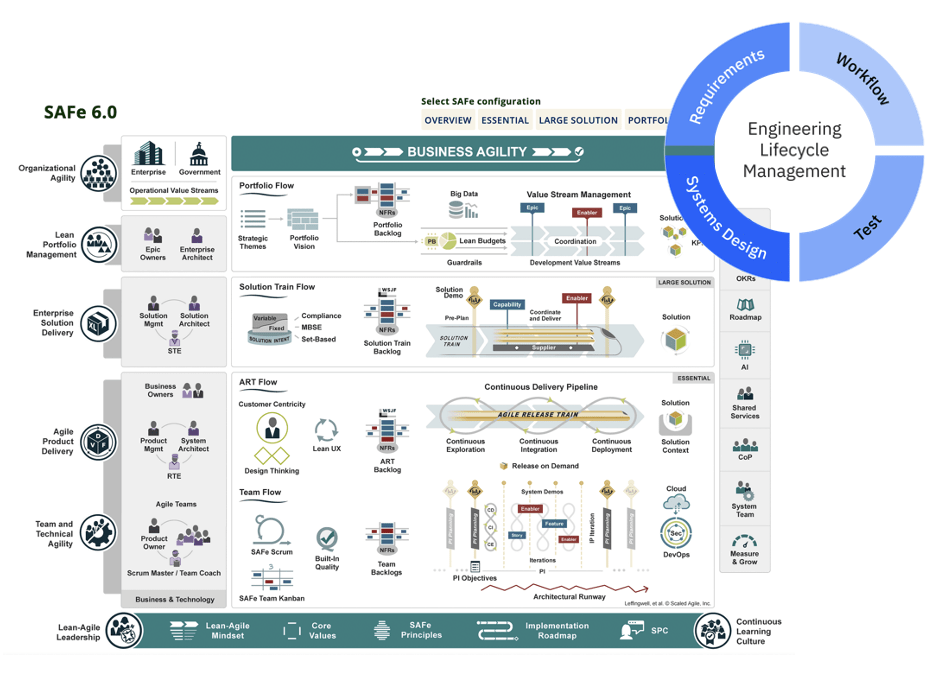

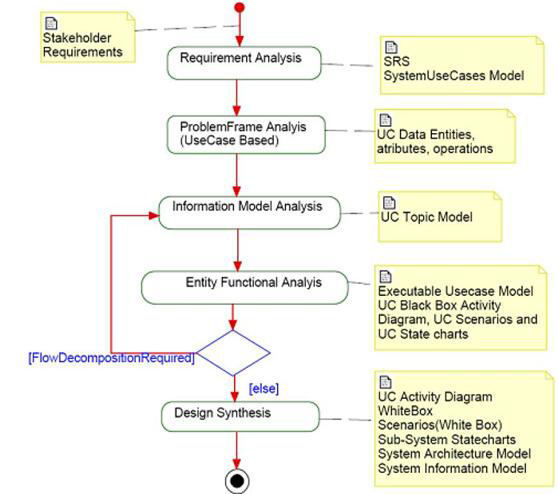

Developing a first-of-its-kind product using the latest technologies is always a challenge. For assistance in the venture, Fagor Industrial engaged an expert team from ULMA Embedded, an IBM Business Partner. The ULMA team proposed adopting IBM Rational Rhapsody Designer for Systems Engineers to help accelerate the pace and improve the quality of development.

Imanol Lukas Etxarri, an Electronic Engineer in the Research and Development Department at Fagor Industrial, explains: “We have worked with ULMA Embedded Solutions many times in the past, and they are one of our key strategic partners. When we decided to develop a new touchscreen washer extractor, we knew that it would be difficult, so we engaged ULMA Embedded Solutions to help us on the journey.

“We have a very strong relationship with ULMA because their engineers have an in-depth knowledge of the latest market trends, best practices and cutting-edge development tools. When they advocated Rational Rhapsody for this particular development, we were quickly convinced that it was the right recommendation.”

Results story

Achieving a clean sweep

Previously, Fagor Industrial built new embedded systems by first manufacturing the hardware, then developing the software using the C programming language, running on microcontrollers. Although most of the company's previous products had fewer functions and a simpler interface than the new touchscreen washer extractor, the programming was complex and time-consuming.

In addition, the traditional development process required significant investment in building a physical prototype before the company could obtain feedback on the product from marketing and other departments, and then finalize the design.

With Rational, all that has changed, as Imanol Lukas Etxarri explains: “Rational offers a broad array of advantages in developing a new product. For example, it allowed ULMA Embedded Solutions to begin by designing all of the hardware on the computer, and simulate the results.

“This meant we could show detailed simulations of the new product to our customers, marketing personnel and executives to obtain their feedback. We worked with them to get the look, feel, functionality and usability of the new product right before we built physical prototypes—resulting in major time and cost savings.”

Additionally, the flexibility of the Rational solution made it easy for ULMA Embedded Solutions to develop new functions requested by Fagor Industrial—such as personalized washing cycles—and incorporate them into the new washer extractor's control panel and processes.

As the development team made changes to the definitions of the washing cycles, the Rational software automatically updated any dependent processes—for example, telling the drum when to spin, empty or fill with water. Thanks to this automation, ULMA Embedded Solutions was able to develop the hardware for the new washer extractor 25 percent faster than expected.

Imanol Lukas Etxarri continues: “Thanks to ULMA Embedded Solutions and Rational software, we were able to cut time-to-market by up to 30 percent. Because we launched our touchscreen washer extractor before our competitors brought their products onto the market, we gained first-mover advantage. Our offering has been a hit with customers because it offers a user-friendly touchscreen and helpful features for personalized wash cycles.”

He adds: “With any innovative product, you can expect to encounter some service and support issues immediately after the launch. However, with our touchscreen washer extractor, we experienced far fewer issues than expected. Because we identified and solved many potential problems in the simulation stage, we have been able to achieve a higher standard in the end product.”

In the future, Fagor Industrial plans to enhance its touchscreen washer extractor with internet connectivity, tapping into the trend towards smarter laundries. As a result, customers will be able to control the devices remotely.

Building on its success, Fagor Industrial also plans to streamline the design of future products using Rational, enabling it to respond rapidly to emerging customer demands and hot trends in the market.

About Fagor Industrial

Headquartered in the Spanish town of Oñati, Fagor Industrial S. Coop. manufactures products for cooking, cleaning and chilling food on an industrial scale. The company is the leading producer of machinery for the hotel and catering sector in Spain, and is among the top ten manufacturers in this market segment in the world. Employing 1,800 people across eight production plants and 18 sales offices, Fagor Industrial serves customers in 90 countries.

Solution components

Take the next step

To learn more about IBM Rational Rhapsody Designer for Systems Engineers, please contact your IBM representative or IBM Business Partner, or visit the following website: ibm.com/software/products/en/ratirhapdesiforsystengi

Founded in 2009, ULMA Embedded Solutions specializes in providing engineering services to support the entire lifecycle of electronic products—from concept to manufacturing and maintenance, including design, development and test phases. The company is based in Oñati, Spain. To learn more about ULMA Embedded Solutions, please visit: www.ulmaembedded.com/en

View more client stories or learn more about IBM Watson IoT